Digital Twin technology is an emerging concept that has been garnering a lot of attention lately due to its immense potential for industries. Gartner predicts that by 2022, over two-thirds of companies that have implemented IoT will have deployed at least one digital twin in production.

Industry 4.0 is a revolutionary movement that has provided increasingly interconnecting components to the industrial sector through the use of technology. Among the several tools that emerged from industry 4.0, one has been calling the attention due to its revolutionary outcome: The Digital Twin technology, which has been used in industry to raise productivity by planning and optimizing the process of collecting and analyzing data through a continuous flow of data coming from a real asset and being sent to a digital replica.

In this article, let’s take a closer look at what Digital Twin Technology actually is and why it matters to the industrial world.

What is Digital Twin Technology?

One of the earliest concepts for digital twin technology appeared back in 2002, attributed to Dr. Michael Grieves, who developed the concept in his executive product lifecycle management (PLM) courses. As a doctoral student in the 90s, Grieves first devised the strategy, describing it as moving physical work into virtual environments.

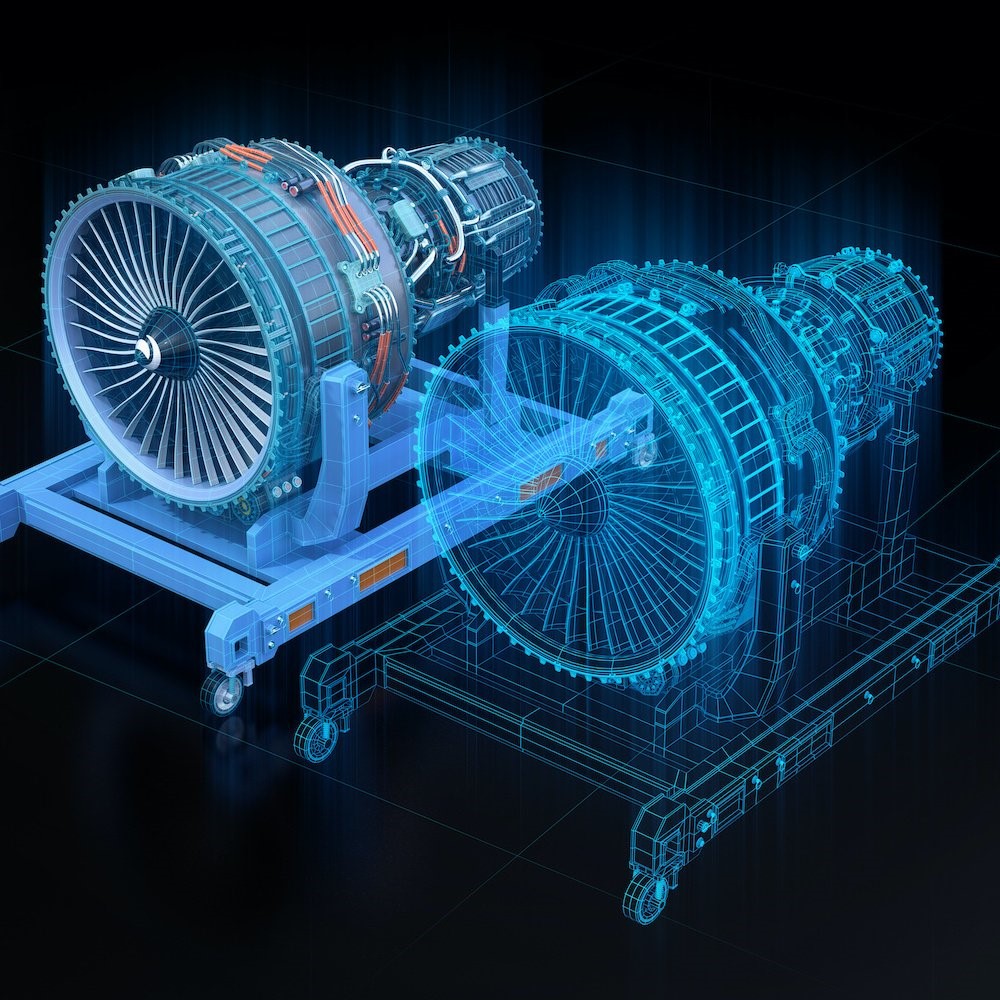

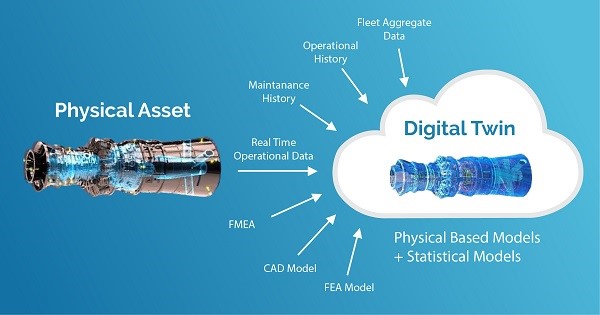

A digital twin is a digital representation of a physical object, process or service. A digital twin can be a digital replica of an object in the physical world, such as a jet engine or wind farms, or even larger items such as buildings or even whole cities. A digital twin is, in essence, a computer program that uses real world data to create simulations that can predict how a product or process will perform. These programs can integrate the internet of things (Industry 4.0), artificial intelligence and software analytics to enhance the output.

With the advancement of machine learning and factors such as big data, these virtual models have become a staple in modern engineering to drive innovation and improve performance. In short, creating one can allow the enhancement of strategic technology trends, prevent costly failures in physical objects and also, by using advanced analytical, monitoring and predictive capabilities, test processes and services.

A digital twin is a virtual model that mirrors a physical object or process throughout its lifecycle. Providing a near real-time bridge between the physical and digital worlds, this technology enables you to remotely monitor and control equipment and systems. Ultimately, it can execute simulation models to test and predict asset and process changes under different “what-if” scenarios.

Leveraging digital twins, companies can realize substantial benefits such as improved operations, product and service innovation, and faster time-to-market.

Creating a digital twin requires different elements, including:

Sensors capturing operational behaviors of assets and processes (vibration, temperature, pressure, etc.), alongside their functioning environments (air temperature, humidity, etc.)

Communications networks providing secure and reliable data transfer from physical devices to the digital world.

A digital platform that serves as a modern data repository pooling and storing shop floor sensor data with high-level business data (e.g. MES, ERP). By combining these data sources, actionable insights can be derived for data-driven decision-making – using advanced AI/machine learning algorithms.

First realized in the aerospace industry, digital twins are now gaining traction across industrial verticals. You can build a digital twin of almost everything regardless of its size – from single components and assets (rotors, turbines, pipelines, etc.) to complex processes and environments (production lines, manufacturing plants, wind farms, etc.). The level of sophistication and detail of your digital twin models depends on the availability and maturity of your IT infrastructure.

At its core, a digital twin is founded on geographic information systems (GIS) technology. An advanced framework for capturing, managing, and analyzing data, GIS uses positions on the Earth’s surface to show items on a map.

As you might imagine, digital twins are useful across a range of industries, combining different types of data into a single view that managers can access at any point in a project’s lifecycle. They can be integrated with a variety of business applications, including:

- Manufacturing execution systems (MES)

- Enterprise Resource Planning (ERP) software

- Supply-chain-specific tools

A digital twin design is made by gathering data and creating computational models to test it. This can include an interface between the digital model and an actual physical object to send and receive feedback and data in real time.

Applications and Benefits of Digital Twins

Digital twin technology renders unprecedented visibility into assets and production to spot bottlenecks, streamline operations and innovate product development. Below are the three major applications of digital twins for Industry 4.0. –

Predictive Maintenance

Gaining a holistic view of the health and performance of equipment, companies can immediately detect anomalies and deviations in its operations. Maintenance and replenishment of spare parts can be proactively planned to minimize time-to-service and avoid costly asset failures. For OEMs, predictive maintenance using Digital Twins can provide a new service-based revenue stream while helping improve product reliability.

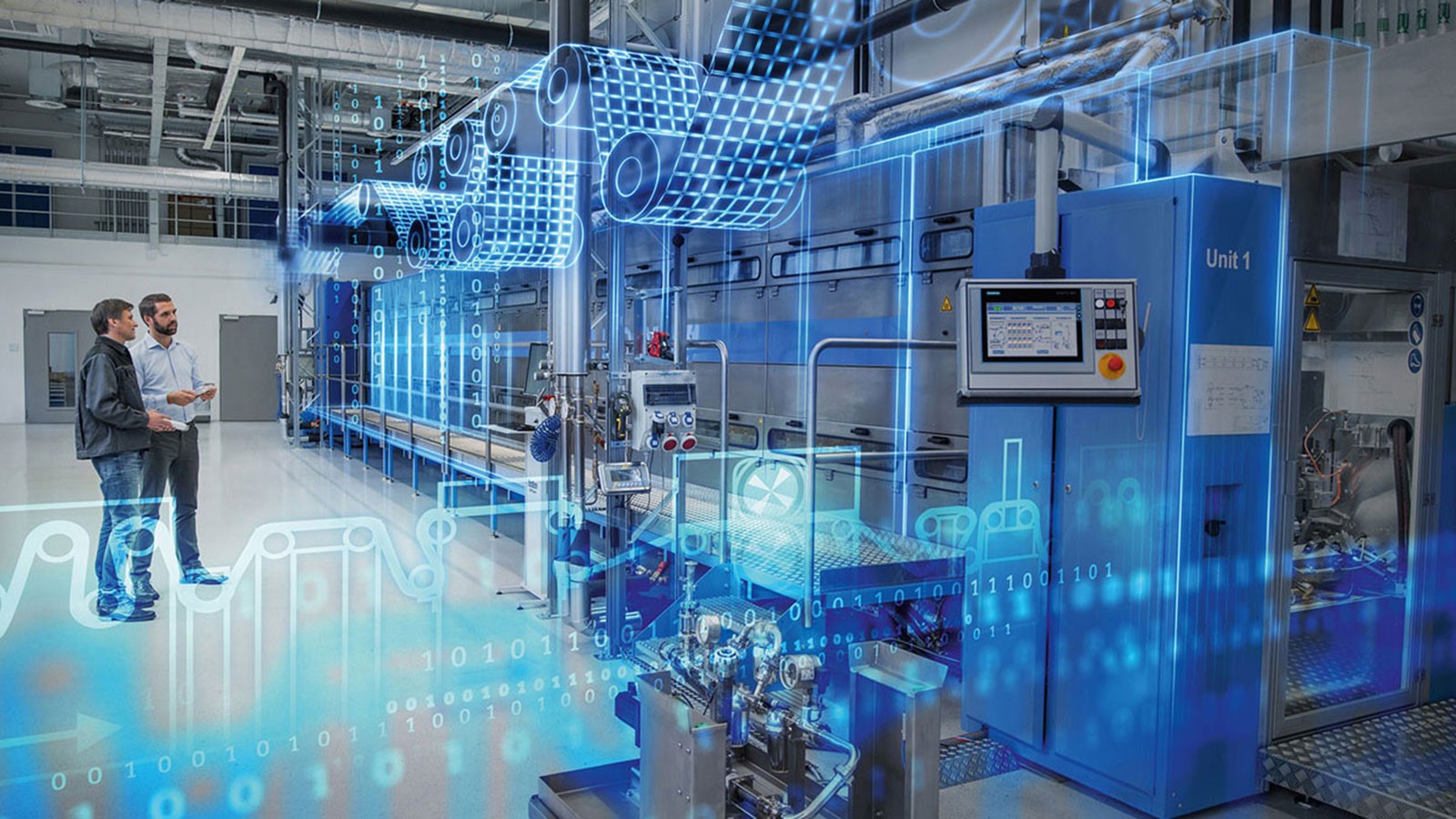

Process Planning and Optimization

A digital footprint ingesting sensor and ERP data of a manufacturing line can comprehensively analyze important KPIs like production rates and scrap counts. This helps diagnose the root cause of any inefficiencies and throughput losses, thereby optimizing yields and reducing wastes. Taking it one step further, rich, integrated historical data on equipment, processes, and environments can enable downtime forecasting to improve production scheduling.

Product Design and Virtual Prototyping

Virtual models of in-use products provide comprehensive insights into usage patterns, degradation point, workload capacity, incurring defects, etc. By better understanding a product’s characteristics and failure modes, designers and developers can correctly evaluate product usability and improve future component design.

Similarly, OEMs can deliver customized offerings for different groups of customers based on specific usage behaviors and product implementation contexts. Digital twin technology additionally aids in developing virtual prototypes and running robust simulations for feature testing based on empirical data.

Digital twins are used in a wide variety of industries for a range of applications and purposes. Some notable examples include:

Manufacturing

Digital twin technology can make manufacturing more productive and streamlined while reducing throughput times.

Automotive

One example of where digital twins are used in the automotive industry is to gather and analyse operational data from a vehicle in order to assess its status in real time and inform product improvements.

Retail

Outside of manufacture and industry, digital twin is used in the retail sector to model and augment the customer experience, whether at the level of a shopping center or for individual stores.

Healthcare

The medical sector has benefitted from digital twin in areas such as organ donation, surgery training and de-risking of procedures. Systems have also modeled the flow of people through hospitals and track where infections may exist and who may be in danger through contact.

Disaster Management

Global climate change has had an impact across the world in recent years, yet digital twin can help to combat this by the informed creation of smarter infrastructures, emergency response plans and climate change monitoring.

Smart Cities

Digital twin can also be used to help cities become more economically, environmentally and socially sustainable. Virtual models can guide planning decisions and offer solutions to the many complex challenges faced by modern cities. For example, real time responses to problems can be informed by real time information from digital twins to allow assets such as hospitals to react to a crisis.

The benefits that digital twin technologies offer your business include:

Increased reliability of equipment and production lines.

Improved Overall Equipment Effectiveness (OEE) through reduced downtime and improved performance.

Improved productivity.

Reduced risk in various areas, including product availability, marketplace reputation, and more.

Lower maintenance costs by predicting maintenance issues before breakdowns occur.

Faster production times.

New business opportunities such as mass customization, mixed manufacturing, small-batch manufacturing, and more.

Improved customer service as customers can remotely configure customized products.

Improved product quality and enhanced insight into the performance of your products in multiple real-time applications and environments.

More efficient supply and delivery chains.

Improved profits.

Digital twins offer a real-time look at what’s happening with physical assets, which can radically alleviate maintenance burdens. Chevron is rolling out digital twin tech for its oil fields and refineries and expects to save millions of dollars in maintenance costs. And Siemens as part of its pitch says that using digital twins to model and prototype objects that have not been manufactured yet can reduce product defects and shorten time to market.

The Future of Digital Twin Technology

Digital twins are already helping organizations stay ahead of digital disruption by understanding changing customer preferences, customizations and experiences. This knowledge means businesses can deliver products more rapidly, with higher quality, from the components, to the code. Yet the promise of digital twin can still go further.

The use of cognitive computing increases the abilities and scientific disciplines in digital twin technology. Technologies and techniques such as Natural Language Processing (NLP), machine learning, object/visual recognition, acoustic analytics, and signal processing are just a few of features augmenting traditional engineering skills. Cognitive digital twins can take us beyond human intuition to design and refine future machines.

No more “one-size-fits-all” model. Instead, machines are individually customized. That’s because cognitive digital twin is not just about what we are building, but for whom.